Watch the podium ceremony and the post-race interviews that precede them. Invariably, you will find the winners thanking their team. And this stems, not just from their humility and admiration for the work their team puts together but from the fact that motor sport, in these amazingly complex and technical times, is truly a team sport.

This has been witnessed on several occasions. For example, the races in Motegi, Japan are usually a gamble given the erratic weather conditions. While the race leader contemplates an entry into the pits for a wet weather bike, the engineers and mechanics are busy setting up the second bike to suit the changing conditions. Although the scale and magnitude of things might be toned down for the Indian National Motorcycle Racing Championship, it still continues to be the cornerstone of motorcycling performance in the country for racers and tuners alike. Having worked at a race team as pit crew, here is a first-person account of how a typical National Championship weekend goes down from the pits.

It typically begins at least a month earlier when the bikes are prepared or rebuilt according to feedback from the riders in the previous round. Once done, the bikes, tools, equipment, spares and consumables are shipped to the track on the preceding Monday. The team and the riders arrive on Wednesday. The pit is set up and the trucks are unloaded by the afternoon. After the set-up, the bikes are checked again for any last-minute jobs, followed by a few sessions of paid practice. Based on the riders inputs, further changes are made to the bike. Mechanical changes come first.

For instance, the gearing for the Kari Speedway in Coimbatore calls for a strong third and fourth ratio. Whereas, the longer MMRT in Chennai calls for a different set-up aimed at top-end performance in fifth and sixth gears. Gearbox overhauls go way into the night. Thursday too is spent in paid practice and the mechanical changes are fine-tuned. With just 45 minutes to an hour between the sessions, mechanical work is conducted at lightening speeds. Changes to the engine may involve a bore-kit overhaul for the appropriate compression. Cylinder heads of different port profiles form a part of the spares bin. Friday, the event begins with free-practice sessions and the finer aspects of the bike are taken in to consideration. For example, a flat-spot in the rev range or a disruption in power delivery is addressed with the appropriate mapping. Suspension settings such as the pre-load, rebound and compression are adjusted to suit the rider’s taste. Fresh tyres are mounted and fine tuning continues before qualifying on Saturday.

The pits are abuzz with activity on Saturday morning as riders ready themselves for qualifying. Last-minute changes based on the weather are carried out. Engine mapping is changed according to the atmospheric pressure at the time of qualifying. Success in qualifying is a springboard to success in the race. Any other changes, if required by the riders, are conducted before race-day.

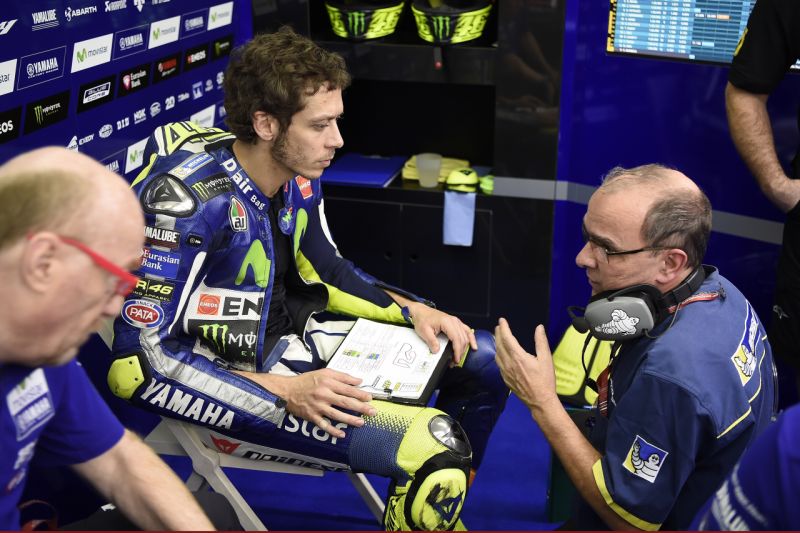

On race-day, a thorough final check-up is done before the lights go out. A number of variables affect the result and the most important variable is the rider. The precise and detailed feedback from him/her plays a pivotal role in this aspect. What comes to mind when discussing the rider feedback, is this quote from the book, Zen and the Art of Motorcycle Maintenance

“The test of the machine is the satisfaction it gives you. There isn’t any other test. If the machine produces tranquillity, it’s right. If it disturbs you, it’s wrong until either the machine or your mind is changed.”

All riders seek this tranquillity and the job of the crew is to put together a motorcycle that delivers it.

While the podium is large enough for just the top three, the champagne eventually gets sprayed on the onlooking jubilant team in parc ferme.

Leave a Reply